The good news when shopping for the right sewer inspection camera is that you have choices. The bad news is that you have many factors to consider to make sure you pick the right camera for your needs. We’ve summarized some of the aspects you should consider before making the call on which pipeline inspection camera will work for you. As you answer each of these, keep in mind the size and accessibility of the pipes you will be inspecting.

Understanding High-Definition (What is Resolution?)

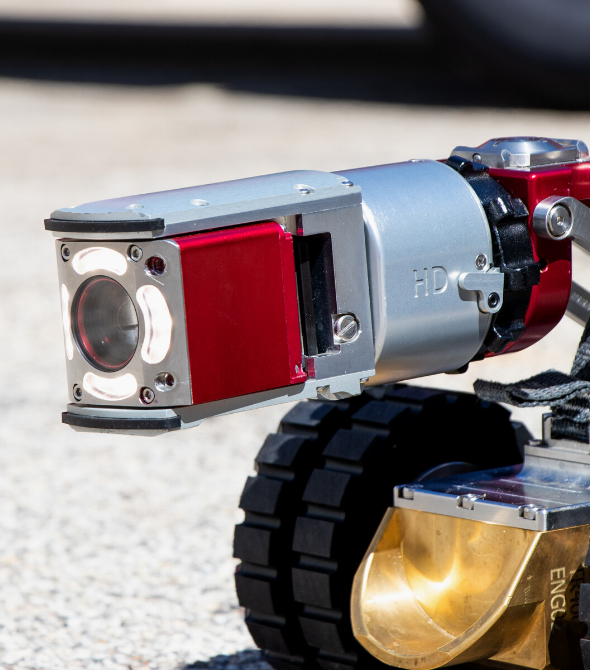

One of your first decisions to make is camera resolution. Older CCTV cameras use analog signals with standard definition resolution. How do you define resolution? Resolution refers to the number of pixels in an image. A pixel is so tiny you can’t see it with the naked eye but when you add more pixels together, they make a complete image. The more pixels, the more detailed that image and the higher the resolution.

Standard definition (SD) includes resolutions (pixel height) at or below 480p. High definition (HD) includes resolutions at or above 720p. “Full HD” images are 1080p resolution. 1080p resolution means the image has 1920 pixels horizontally by 1080 vertically (1920×1080). You can find the total pixels in the image by multiplying those two numbers (the height and width) together, meaning a 1080p image has more than 2 million pixels. Full HD is just another term for 1080p or 1920×1080, and those are all ways of referring to the same resolution.

As always, the higher the resolution, the sharper the picture will be. Such high resolution is what gives HD video its sharpness and realism. However, keep in mind that the higher the resolution of the cameras, the more bandwidth and hard drive space you will need to transfer and store it.

High definition is only possible with a digital control system. A controller area network (CAN) bus is a high-integrity serial bus system for networking intelligent devices. CAN busses and devices are common components in automotive and industrial systems.

Bosch originally developed CAN in 1985 for in-vehicle networks. In the past, automotive manufacturers connected electronic devices in vehicles using point-to-point wiring systems. Manufacturers began using more and more electronics in vehicles, which resulted in bulky wire harnesses that were heavy and expensive. They then replaced dedicated wiring with in-vehicle networks, which reduced wiring cost, complexity, and weight. CAN, a high-integrity serial bus system for networking intelligent devices, emerged as the standard in-vehicle network. The automotive industry quickly adopted CAN and, in 1993, it became the international standard known as ISO 11898.

CAN provides significant benefits including:

- Instantaneous response for camera/tractor commands plus multiple controls simultaneously

- Programmable autonomous time-saving functions such as auto-drive to waypoints & auto-retrieve

- Alert capabilities such as graphical crawler roll-angle display for roll-over risk; loss of seal integrity; internal pressure, temperature & humidity monitoring

Note: Analog components are becoming more difficult to source as companies promote digital systems.

Consider Zoom Levels When Selecting Sewer Inspection Cameras

What is the zoom range of the pipeline inspection camera you are considering and how much zoom do you really need? The right zoom for you will vary depending on the job environment. Smaller diameter sewer pipes limit the distance you can see. Pipe inconsistencies, like bends and sags limit how much light you can project down the pipe, which means you do not need maximum zoom. Conversely, larger storm drains allow you have to see further down the pipe, especially with auxiliary lighting. In this case, you would be able to zoom more and should look for that capability in your sewer inspection camera selection.

RELATED: Aries Voyager HD Mainline Inspection System

Ideal Lighting on a Sewer Inspection Camera

Does the sewer inspection camera have LED lighting? LEDs provide longer life, brighter lights and you don’t have to worry about burning them out since they don’t run hot and have built-in trip circuits.

The Role of Sewer Camera Pressurization

Electronics and moisture do not go well together. Sewer inspection cameras operate in wet conditions, sometimes in high humidity locations and often are subject to nighttime dew. Verify whether the camera is pressurized with nitrogen or air. We recommend nitrogen since it is a dry gas, which keeps the electronics dry with positive pressure. This is important so if the camera is submerged, the risk of damage to the camera is minimized.

On Aries Industries WiperCam® inspection camera, the camera is fitted with a regulator and comes with an external canister of nitrogen to pressurize the camera. Onboard diagnostics allows you to monitor how much nitrogen there is. The regulator will shut off if necessary to ensure you will not over-pressurize the camera.

Pro Tip: We always recommend checking camera pressure every day as part of startup procedures. You should keep a log book to monitor any trends happening with the camera. For example, let’s say you originally pressurized the camera every month, but now it’s every week or even every day. This may alert you that a seal or 0-ring needs replacing.

The Need for Adaptability When Replacing a Sewer Camera

If you are looking to replace a sewer inspection camera, it may be important for it to be compatible with older versions of inspection tractors.

Note: Aries WiperCam has an adapter so that it can easily pair with our older tractors.

How In-the-Pipe-Lens-Cleaning Saves Time and Money When Completing Sewer Inspections

Sewer inspections often happen in tandem with pipe cleaning. If the sewer camera is following a jetting nozzle, the lens can get splashes that leave water marks, obscuring the view of the pipe. Another difficulty in inspecting a sewer line is grease in the flow. If grease gets on the camera, it leaves a sheen, preventing a clear view of the pipe.

If the camera is equipped with lens cleaning technology, you will not have to retrieve the camera to clean it off. This is important to maximize your time in the pipe. If the camera does not have this capability, when the lens is obscured by debris, you would need to pull it out, hose it off and then get it back in the pipe and hope you don’t hit the same challenging spot again resulting in more debris on the lens and another work stoppage.

Aries WiperCam and the Voyager™ HD Mainline Inspection Camera both use in-the-pipe lens cleaning technology to maximize uptime. Here’s how it works. The lens pans/tilts and rotates to clean the lens. The backside of the frame is equipped with a blade. When the lens is rotated 360°, it skims across the blade to remove the debris.

This technology allows you to complete inspections without having to remove the camera and start again. You can easily navigate through bellies in the pipe that have grease or debris that mucked up the camera, clean the lens and keep on inspecting the pipe. Your work will be completed faster and you’ll have more flexibility in working in pipes that are not perfectly clean.

Durability & Field Repairable – A Necessity for Sewer Inspection Cameras

A priority of anyone working in the challenging environment underground is to have equipment that is durable and can easily be repaired in the field to keep crews moving forward on the job. Make sure you know the quality of materials used in the construction of the inspection camera and how easily it is to access parts and complete minor repairs on the job site. For example, with the WiperCam, operators can easily replace the wiper blade in the field when needed. This minimizes equipment downtime and saves customers money.

Easy Access to Service & Parts

Key to any inspection equipment purchase is to work with a reputable manufacturer with high-quality, accessible service centers and easy access to replacement parts. Aries provides a Total Support program where customers can typically resolve equipment issues through our expert phone support. When needed, repair service can be obtained through Aries service centers in Wisconsin and California or at any of our vetted dealer locations. As a US-based manufacturer, we are able to quickly provide replacement parts and even offer a free loaner program to maximize uptime in the field.

Asking the right questions when you are shopping for a sewer inspection camera can help make sure you have the best equipment for the job at hand.