wolverine® 2.0 cutter

SOLUTIONS

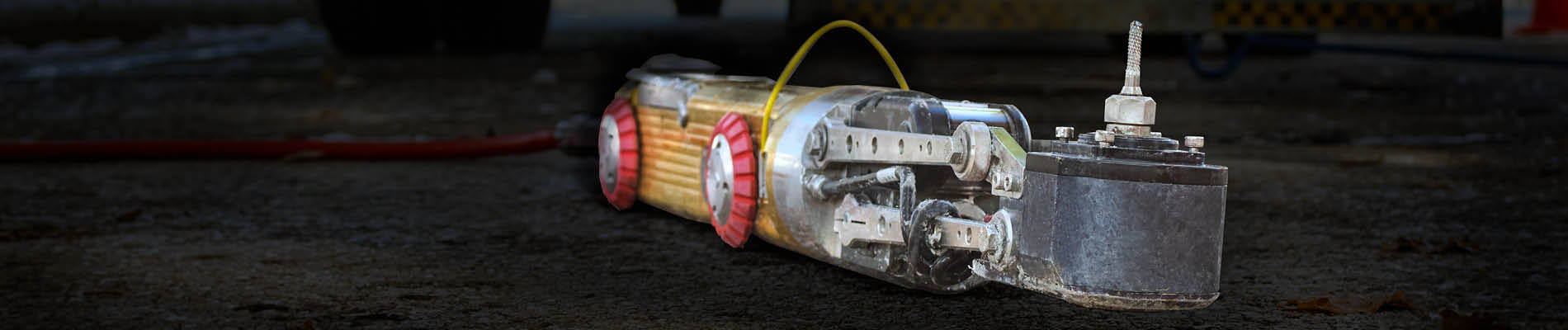

Wolverine® 2.0 Self-Propelled Robotic Electric Cutting System

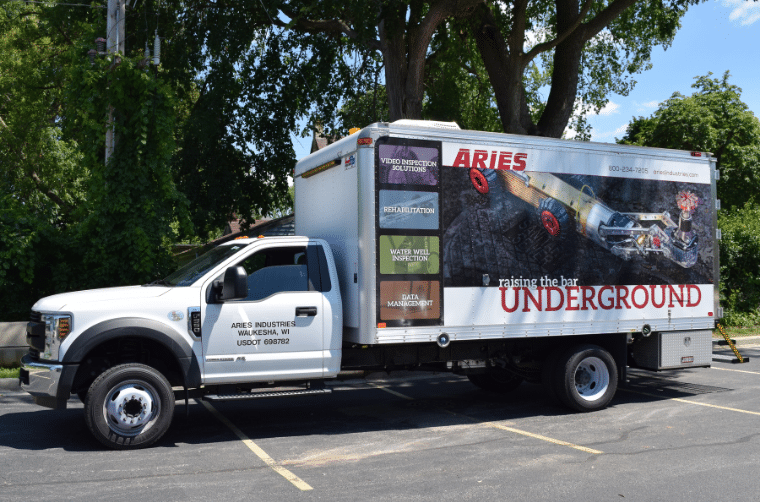

The Wolverine 2.0 Self-Propelled Robotic Electric Cutting System is compact, powerful, and able to navigate and cut through challenging pipes. The vehicle-mounted system is designed and built at Aries US-based plant with stainless steel and brass construction and integrated electrical cabling.

The Wolverine® 2.0 Cutting System includes:

- Powerful crawler to maneuver around obstacles

- Reel with 850′ of cable to minimize set uptime

- Camera with in-the-pipe lens cleaning technology

The vehicle-mounted system is designed and built at Aries US-based plant with stainless steel and brass construction and integrated electrical cabling.

Model CT2750

Overall System Specifications Includes Controller, Crawler, Camera, Reel.

- CANbus technology

- Ergonomic fingertip controls

- Dual joystick

- Touch screen display

- Integrated DVR

- Fixed lens with field replaceable glass

- Built-in lens wiper and scraper for in-the-pipe lens cleaning

- Adjustable LED light ring

- Homing feature

- Weight: 61 lbs.

- Length: 37″

- Operates in 6″-18″ diameter pipes

- Compact profile

- All-wheel drive

- Multiple wheel options

- Suitable for use in water lines

- Cable length: 850′

- Diameter: ¾”

- Coax video

- Material: Kevlar®, Nylon, Hytrel®, and Polyurethane (red)

- Strength: 2,000 lbs.

- Reel weight: 400 lbs.

- Electric

- 1kw@7000-12000 RPM

- Adjustable speed setting

- Field repairable

- 24″ diameter pipe kit fits existing cutter body so only one cutter body needed for 6″ to 24″ pipes

- 4th axis allows you to roll the tool bit forward for challenging cutting

Powerful & Precise Cutting

- All-wheel drive and compact profile to navigate challenging pipe conditions

- Infinitely adjustable speed and axis movement for precision cutting

- Stabilizing lift ensures balanced operation

Advanced Operator Control

- Fingertip control for outstanding operator ergonomics

- Dual joystick allows for accurate cutting head positioning

- Multiple wheel configurations to match pipe conditions

Maximum Uptime

- Quick truck set up and tear down

- In-the-pipe lens cleaning technology

- Easily accessible replacement parts