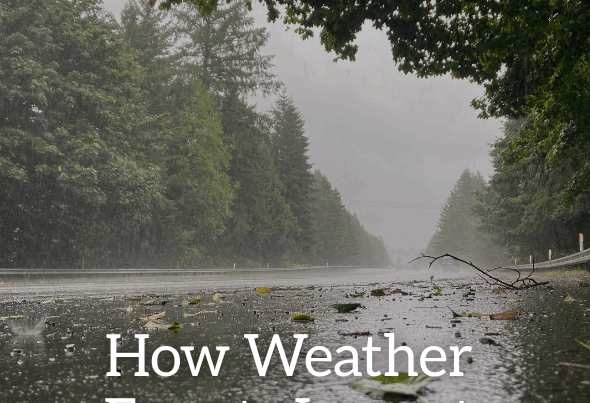

One of the most common issues we see in the repair shop at Aries Industries is water intrusion into a sewer inspection tractor or camera, causing a customer to delay work in the field. To make matters worse, fixing the issue often includes an expensive repair bill. The picture below shows an extreme version of water in the housing, but even just a little water getting into your inspection equipment can quickly cause big problems.

Here are a few ways to greatly reduce the chance of water infiltrating and damaging your equipment so you can continue to log accurate footage of pipeline conditions.

Pressure Checking and Humidity Monitoring

The first two preventative maintenance tasks we recommend you complete are pressure checking and monitoring humidity. These are the tasks we think of most often and both are easy to do, yet are commonly skipped.

Pressure Checking – Too often we see that pressure checking a unit is an afterthought when out running lines. When we train customers, we advocate that it only takes a minute to do a quick pressure test before you put it in the line. Establishing this as a routine habit every time you set up will save you in the long run. It is far better to detect a leak before putting inspection equipment underground, causing water to get in and stopping production.

Monitor Humidity – Another habit to get into is to keep an eye on humidity levels. If humidity starts to get too high, take the pipeline inspection equipment out of service and figure out what is causing the problem. Fixing the equipment early will be easier and less expensive and prevent high humidity from ruining expensive internal components.

Seal Failure

Even if you do pressure checks and watch humidity, you can have a sudden intrusion of water due to seals that are old and fail while the unit is in use. The easiest, and yet often skipped, solution to this issue is to have a maintenance program to change seals. It is the single most proactive thing that you can do to prevent failures in field.

Preventative Maintenance of Seals – O-rings and rubber seals deteriorate over time. Submerging them in water and then drying them out over a year or two will push them to a sudden failure. Naturally this often happens at the worst possible time!

Depending on your usage of the pipeline inspection tractor or camera you may need to change your seals out every six months to a year to be sure they are in good condition and protect you from water damage. A planned maintenance schedule where you remove units from service during downtimes and when it is most convenient for you is far better than a possible failure when you can’t afford it.

The Aries Industries Total Support team is here to help you no matter if you just need some information on this process, need parts for you to reseal your units, or want to send it to us to reseal it for you. Call us at 1-800-234-7205 and follow the prompts to get technical help or talk to customer service for parts and repairs. We are looking forward to helping you maximize your uptime on your Aries equipment.