case study

How Induracoat is Reinventing Water Main Rehabilitation in Canada and Beyond

Summary

In neighborhoods across Canada, residents often have no idea that just beneath their feet, aging water mains are being restored to like-new condition—all in the span of a single day. That’s the promise behind Induracoat, a company that’s redefining how municipal water infrastructure is maintained with a process that’s as innovative as it is efficient.

At the core of Induracoat’s success is its mastery of Spray-In-Place Pipe (SIPP) technology, a trenchless rehabilitation method that eliminates the need for disruptive excavation. Once inside the pipe, they clean and dry it, then apply a spray-on polymer lining that effectively creates a new pipe within the old one.

What makes their approach especially impressive is their commitment to same-day return to service. Residents experience a brief interruption in water supply, but by the end of the day, service is restored—no bypass lines, no drawn-out construction zones, and no surprises.

A Process Built for Speed and Precision

Behind the scenes, that speed and reliability come from a tightly controlled process. Before any lining is applied, Induracoat inspects the pipe to ensure it’s clean and free of standing water, while also pinpointing service connections that need to remain open. After the lining is cured, a second inspection confirms the pipe meets specifications and that all connections are intact.

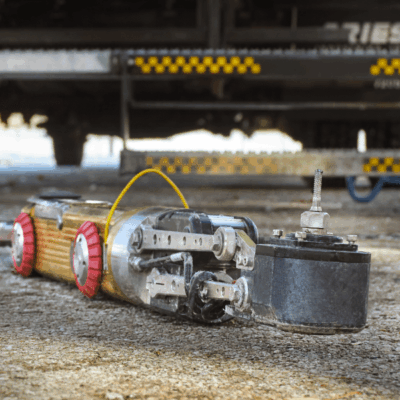

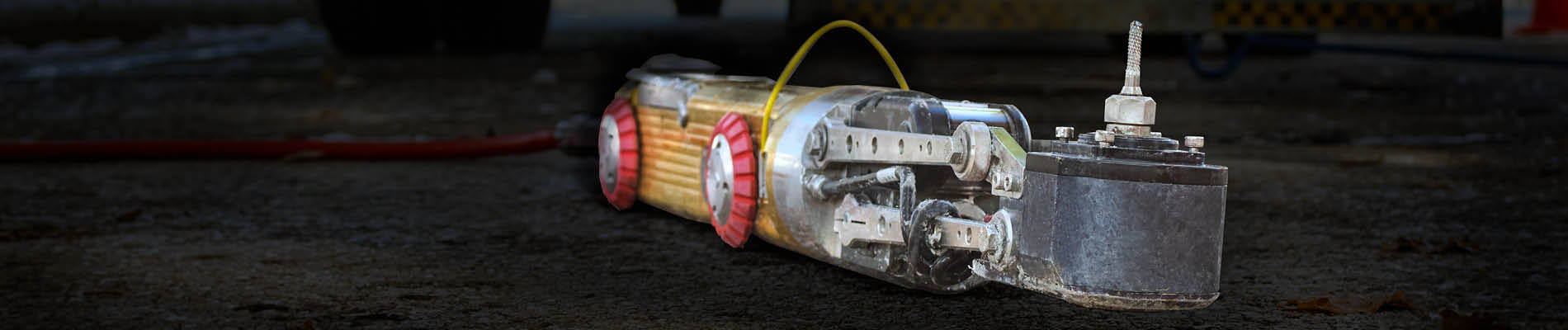

That’s where technology quietly plays a supporting role. Induracoat has used Aries Industries’ inspection systems since their very first project over a decade ago. The Pathfinder system helps them verify conditions before and after lining. And when fast response is needed to re-open any plugged connections, their crews turn to the Wolverine robotic cutter—chosen for its speed and ability to navigate pipes independently, saving valuable time when every minute counts.

“Every minute counts when you promise same-day return to service. Our process-and the equipment we trust-lets us deliver on that promise, project after project,” according to Doug Ritch, Induracoat President. “Aries’ camera and cutter systems are critical to the success of our projects. The level of service we get from Aries is second to none. I can’t recall a time when an equipment failure impacted our ability to get the job done same-day.”

Expanding Horizons

As demand grows for smarter, faster infrastructure rehabilitation, SIPP technology is attracting greater attention worldwide. Induracoat’s ten years of proven success in Canada has led to the licensing and launch of SIPP Americas LLC, a Texas-based company delivering the SIPP process to clients across the United States and Mexico. Backed by the same high standards for efficiency, cost-effectiveness, and minimal disruption, SIPP Americas helps municipalities across North America tackle their aging water systems—without digging up a single street.

Learn more about:

Client

Induracoat

Industry

Mainline Inspections & Rehabilitation

Location

Canada

WHAT IS SIPP?

Spray-In-Place Pipe (SIPP) is a trenchless method for rehabilitating pressurized water mains without excavation. A polymer lining—such as Resiline® 320, used by Induracoat—is sprayed inside cleaned pipes, forming a seamless structural barrier that resists corrosion and extends the pipe’s life.

Key Benefits:

- Minimal surface disruption

- No need for bypass water lines

- Safe for potable water

- Restores service same-day

This approach is helping municipalities tackle aging infrastructure efficiently and economically.

Let's Talk

Ready to learn more about how Aries can help you raise the bar underground? Our team is standing by to help you with answers about our solutions and products.